Choosing the right spill kit for your workplace is vital to ensuring the safety of your team and members of the public and will involve considering several factors to ensure that your spill kit meets the specific needs of your business.

In this blog, we will discuss some basic steps to help you select the most appropriate spill kit for your workplace.

Carry out an Assessment of Potential Hazards

Identify the types of substances or materials present in your workplace that could potentially result in a spill. Some common hazardous substances in the workplace may include acids, caustic substances, disinfectants, glues, pesticides, oils, and solvents.

You should understand the properties of these substances and any specific risks associated with them. You should also consider the less obvious substances found in workplaces such as paints, detergents, and fuels used in machinery.

Evaluate Potential Spill Quantities

You will need to carry out an evaluation of possible spill sizes – you will need to estimate the maximum volume of potential spills in your workplace. This evaluation will help you to choose the size of a spill kit, or the number of spill kits, required to adequately protect your workplace based on absorbent capacity.

You might consider worst-case scenarios or past spill incidents to get a rough idea of the possible spill volumes you may typically encounter.

As a general rule, the size and quantity of the spill kit you need should be:

- At least equal to your largest container on-site; or

- 25% of the total volume you would move on a pallet. For example, say you are moving a pallet containing 24 x 20L drums (480L); you would as a minimum require a 120L spill kit on-site.

Understand Spill Response Requirements

Different spills at the workplace may require different response actions. Understand your business’ spill response plan (including any internal policies) and if applicable, any regulatory requirements applicable to your specific industry. Factors for consideration may include containment, neutralisation, and special handling procedures.

Know Your Workplace Environment

You will need to evaluate and consider your physical workplace characteristics and environment where spills are most likely to occur. Consideration should be given to location (indoor or outdoor or near waterways), your surface type (concrete, soil, water), and the contours of your workplace (potential for spills to migrate and spread).

These factors will influence the spill kit you choose and if you require any additional equipment for your spill response.

Select Your Spill Kit Type

Based on your assessment and consideration given to the above, you can now select the most appropriate type and size of spill kit for your workplace. The most common types of spill kits are:

a. General Purpose Spill Kits

General Purpose Spill Kits (also known as universal spill kits, all-liquid spill kits, or environmental spill kits) are designed for any workplace or public space which deal with less harmful water-based liquids such as coolants, paint, blood, bodily fluids, degreasers, agricultural chemicals, and other non-aggressive chemicals (mild acids, bases, and water-based chemicals).

A General Purpose Spill Kit is the ideal solution for hospitals/medical centres/pathology centres (also called lab, medical, and blood spill kits), hotels/motels, commercial kitchens, shopping centres, schools/colleges/universities, and aged care facilities.

b. Oil & Fuel Spill Kits

Oil & Fuel Spill Kits are designed for workplaces dealing with oils or fuels (hydrocarbons), including workplaces where vehicles or machinery have oils, fuels, petroleum, diesel, or grease inside them. An Oil & Fuel Spill Kit is suitable for petrol stations (also called petrol station spill kits), mechanics (also called automotive spill kits), manufacturing, factories, transport & delivery (also called vehicle spill kits), marinas/maritime industry (also called marine spill kits), public & private car parks and construction sites.

Oil & Fuel Spill Kits are also ideal to keep within transport vehicles that transport oil & fuel, or transport machinery that contain oil and fuel inside them.

c. Chemical Spill Kits

Chemical Spill Kits (also known as Hazchem Spill Kits) are designed for workplaces dealing with harmful chemicals. Chemical Spill Kits are suitable for chemical plants and manufacturers, laboratories, factories, industrial facilities, laundries/dry cleaners, minesites, and any other workplaces that use or store harmful chemicals.

A Hazardous Chemical Spill Kit can be used for strong acids (sometimes known as acid spill kits) & bases (alkalis), hydrochloric acid, phosphoric acid, sulphuric acid, sodium hydroxide, hydrofluoric acid, solvents, herbicides, pesticides, and the like.

Assess the Spill Kit Components

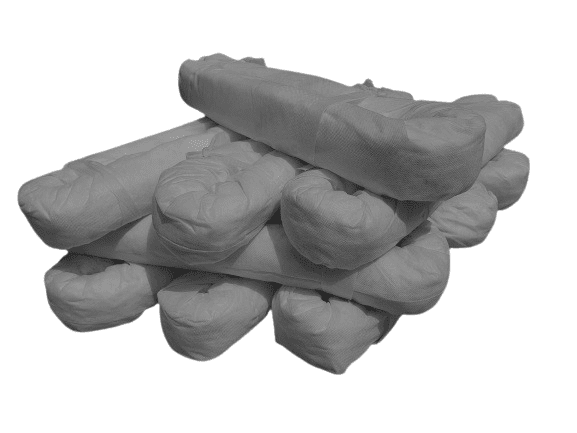

Evaluate the contents of the spill kit to ensure they meet your specific needs and requirements. Key components of your spill kit may include absorbent pads, booms and pillows, waste disposal bags, gloves, and goggles.

1.2m General Purpose Absorbent Booms

Consider Additional Equipment

Depending on your business’s specific spill response needs, you may determine that you need additional equipment such as loose or granule absorbent, shovels, brooms, or specialised personal protective equipment such as respirators.

Evaluate if these items are necessary for your workplace and consider including them with your spill kit.

Review Regulations & Standards

Familiarise yourself with industry-specific regulations and standards that govern your spill response and containment requirements. You should ensure your chosen spill kit complies with these requirements.

Training & Maintenance

Your team should be given training on the proper use of spill kits to ensure they are used efficiently and safely. They should be familiar with your spill response plan. The disposable bags should be disposed of in accordance with local, state, and national EPA regulations. The disposal will depend on the properties of the liquids. If you are unsure, there are local waste departments you can call and make an enquiry.

In addition to this, it is important to establish a maintenance schedule for the spill kits to check and replace/re-stock components as required. You don’t want to encounter a spill emergency and find that half of your spill kit components are missing.

Review & Update

Regularly review and update. The business environment you are operating in is continuously evolving and so too are your safety requirements. You should periodically reassess your spill response needs and adjust your spill kit selections accordingly.

Changes in the materials you use at your workplace, the quantities of these materials you handle and store, and even changes in work processes may result in the need for an updated spill kit selection. Determine how frequently your spill kits will be inspected, replenished, or replaced.

This blog was aimed to give you a better understanding of choosing the right spill kit for your workplace. By carefully considering all the above factors, you can choose the right spill kit(s) that align with your specific workplace needs and requirements.